A long-term, multi-national research effort driven by Trina Solar has finally paid dividends, with the company announcing the development of a 24.4% efficient, all-rear contact silicon solar cell design that is all set to be commercialised.

The consortium involving Trina Solar, the Australian National University (ANU), the Solar Energy Research Institute of Singapore (SERIS) and an Australian consultancy group, PV Lighthouse, have been working on the Inter-digitated Back Contact (IBC) solar cell design since 2011. According to Dr. Pierre Verlinden, Vice-President and Chief Scientist of Trina Solar, “This marks a milestone in solar cell research with an improved IBC cell efficiency of 24.4%.”

The new efficiency brings IBC cells one step closer to beating the record-holding PERL cell –another Australian invention (developed at UNSW) – which is 25% efficient.

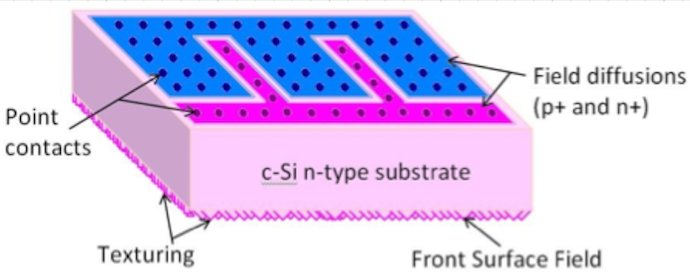

Standard silicon solar cell designs (including UNSW’s PERL cell) have electrical contacts on the front as well as the rear. In comparison, the IBC design (pictured above) has both contacts on the rear of the cell. This has the potential to lower resistive losses and allows cells to be more tightly packed together in a module. The resulting modules have a higher current output as well as better aesthetics.

Rear-contact cell designs have seen a renewed interest of late as new advancements have suggested the possibility of achieving up to 26% using IBC cell designs. Although the 24.4% efficiency achieved in this work is lower than this theoretical maximum, it is only 0.6% less efficient than the long-standing world record of 25% and represents “the highest efficiency independently confirmed for a conventional IBC solar cell to date,” according to Professor Andrew Blakers of the ANU Research School of Engineering.

Diagram of an all back contact solar cell. (Image via Australian National University.)

Diagram of an all back contact solar cell. (Image via Australian National University.)

Very few manufacturers have managed to commercialise high-efficiency IBC modules at low costs, with Sunpower being a notable exception. Although cost details have not been announced yet, Blakers suggested the technology is ready for mass-production. “The work is expected to lead to commercial solar cells with improved efficiency, allowing more power to be generated from a given area of rooftop solar module,” he says.

Trina Solar has previously produced full-size commercial IBC solar cells and 72-cell modules which have achieved over 22% efficiency at the cell level and a module peak power rating of 238W. Lab-made cells, such as the one in the new work, are typically much smaller than such commercial cells; however, if it can be successfully integrated into full-size modules, Trina may soon be able to cross the 260W (peak) mark.

The news is not only a welcome one for Trina and the PV industry, but is also a matter of pride for Australian R&D, which continues to stay relevant and maintain its long history of driving innovation in the PV industry in spite of the dramatic decline of in-country PV manufacturing in recent years.

© 2014 Solar Choice Pty Ltd

- Future of Utilities – Part 1: The death of base-load generators - 11 September, 2014

- Sharp enters energy storage market with SmartStorage - 18 August, 2014

- Phinergy extends electric car range with metal-air battery technology - 13 August, 2014