Solar cells today are made from a wide cocktail of materials, from earth-abundant materials (Silicon and Carbon) to exotic rare earth metals (Indium, Gallium, etc), and from polymers to organic materials. A new research study shows that perhaps it’s time to add wood pulp to that list.

Researchers from University of Maryland, the South China University of Technology, and the University of Nebraska-Lincoln have developed a new wood-fibre based ‘nano-paper’, which may one day replace plastic substrates used in some solar cells owing to its unique optical properties.

In all PV panels, cells must be covered and encapsulated by a protective material to protect them from degradation. However, to achieve high efficiencies, all layers that the incoming light passes through must (a) be highly transparent (to ensure the light goes through) and (b) diffuse the incoming light (to ensure that light going into the material does not get reflected back out easily).

Diffusing light can easily be done by making it hazy – think translucent or scratched glass, but high haziness and high transparency often don’t go together (it’s hard to see through translucent glass). Similarly, highly transparent materials, such as clear glass and plastic used to cover the front (sun-facing) side of a cell in a typical solar panel, have high transparency (90%) but low optical haze values (around 20%).

However, the new paper-like material developed in this study (shown in the top image) was found

to have an ultrahigh transparency of 96% as well as an ultrahigh optical haze of 60% – the highest optical haze value reported so far for such substrate materials.

The new material, made basically from pine wood pulp, acquires such unique properties due to

the extremely small size of the nano-pores formed when wood fibres in the material are made to

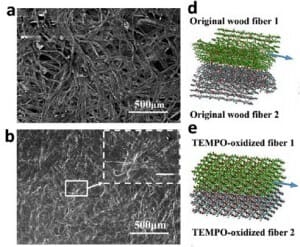

collapse into tight, cavity-free layers through a special heat treatment step that the researchers call the ‘TEMPO’ process. The figure below compares the internal structure of the pulp (top: ‘a’ and ‘d’) and the processed film (bottom: ‘b’ and ‘e’) as seen by an electron microscope.

Click image to enlarge (Image credit: Zhiqiang Fang et al / American Chemical Society)

This development is particularly relevant for organic solar cells – a PV technology that has so far eluded commercialization. Researchers have found that coating the surface of an organic solar cell with their paper-like material boosted its efficiency by an impressive 10%. Dr. Liangbing Hu, an assistant professor at the University of Maryland, explains that gains of up to 20% were possible.

Unlike silicon or thin-film devices, which are opaque, organic solar cells are transparent. This makes the efficiency gains all the more significant, giving these devices a strong edge for building-integrated PV applications. As Dr. Hu explains, “Such low-cost, highly transparent, and high haze paper can be utilized as an excellent film to enhance light-trapping properties for photovoltaic applications such as solar panel, solar roof, or solar windows.”

Not limiting their scope to organic cells, however, the researchers have also coated the new material onto bare silicon and found a 20% improvement in light absorption compared to uncoated silicon. While the significance of this for standard silicon solar cell efficiency is currently unknown (standard solar cells do not use uncoated silicon, so it’s not a fair comparison), these results will certainly interest silicon researchers.

Dr. Hu points out that in addition to using a process that consumes less time and energy than other processes used to create similar ‘nano-paper’, their material can also be deposited more cheaply and simply than plastics, potentially replacing it in niche applications.

The researchers are hoping to successfully integrate their new material into existing devices and further study its stability. If done right, this should go a long way in winning over the electronics and PV industries, which are known to be both, permanently sceptical and secretly hopeful of fantastical claims from new materials. Afterall, who doesn’t want a renewably-sourced, high performing material with a low cost and energy footprint?

Image credit: Zhiqiang Fang et al / American Chemical Society

© 2014 Solar Choice Pty Ltd

- Future of Utilities – Part 1: The death of base-load generators - 11 September, 2014

- Sharp enters energy storage market with SmartStorage - 18 August, 2014

- Phinergy extends electric car range with metal-air battery technology - 13 August, 2014