Researchers at the University of California, Los Angeles (UCLA) have set a new record for organic polymer solar cells, with a device efficiency of 11.5%.

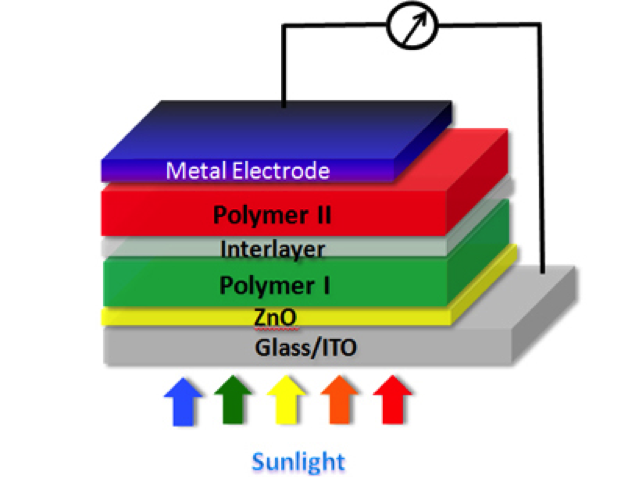

The record-breaking ‘plastic’ solar cell uses what is referred to as a ‘tandem’ structure. There are essentially three specially-tuned solar cells stacked on top of each other to form a more efficient overall device.

The tandem cell is able to make better overall use of the available light by having each layer tuned to absorb a particular wavelengths (or ‘colours’) of light better than the others. As a general rule, the top layer is designed to absorb the more energetic photons (individual light ‘particles’), the bottom layer tuned for the less energetic photons, and the middle cell for those photons in between.

However, the increased efficiency comes at a price. The multi-layered architecture necessitates the use of additional joining layers, which makes fabrication more complicated. The properties of the cells must also be very carefully matched. More specifically, each PV layer must generate the exact amount of current as each of the other layers in order to extract the most performance out of the whole device.

The tandem structure has been widely employed in ultra-high efficiency cells looking to push the boundaries of solar PV efficiencies. The application of a tandem structure to an organic polymer solar cell was demonstrated as early as 2007 by researchers at the University of California, Santa Barbara (UCSB).

Tandem cell structure showing one organic polymer layer stacked on top of another. Image Credit: UCLA Engineering

Plastic solar cells can be made with cheaper materials, produced with scalable manufacturing processes (i.e. spray coating) and have the ability to be deposited onto flexible or curved materials (e.g. outdoor umbrellas and tents). However, they generally have lower electrical conversion efficiencies and currently last only a few years in the field.

Konarka (a previous producer of plastic solar cells) suggested that cell efficiencies of 7–10% were required in order to compete with conventional fossil-fuel powered electricity in the US, as of 2008. Given that the UCLA tandem cell shares many similar materials and features to Konarka solar cells, the 11.5% ‘champion’ cell may have just demonstrated a plastic solar cell design capable of competing directly with conventional electricity. However, there are significant challenges involved with scaling up to high-volume manufacturing.

The UCLA group has made it known that they are aiming for plastic solar cell efficiencies as high as 15%, which is well within the range of typical silicon solar cells we see on Aussie roofs today, but produced at a fraction of the cost. Increases in efficiencies such as this will allow plastic solar cells to expand beyond purely niche applications and compete directly with conventional crystalline silicon solar cells.

Top Image Credit: pv magazine

© 2014 Solar Choice Pty Ltd