In order to make crystalline silicon solar cells, cell producers need micron-thin wafers of exceptional purity. The majority of base silicon material–referred to as ‘polysilicon’–used for producing high purity silicon is made using the Siemens process, a silicon refining method which is effective but very energy intensive. More recently, fluidised bed reactor (FBR) technology has emerged as a cheaper and more effective alternative to the Siemens process.

FBR technology reduces polysilicon production costs by: (i) reducing the energy intensity of the process by up to 90%; (ii) producing more polysilicon per volume of the reaction chamber; and (iii) enabling a continuous process which reduces setup times.

FBR technology was implemented in large scale solar cell production by REC in 2006 and currently accounts for just over 15% of polysilicon production worldwide. More recently, Sun Edison have announced their own high pressure FBR technology will be a major factor in enabling crystalline silicon solar cell module costs of 40c per watt by 2016.

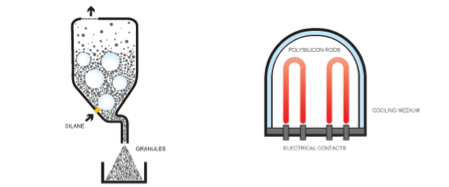

A fluidised bed reactor produces high purity silicon granules by suspending small silicon particles in heated silane gas. The high velocity silane flows react with small silicon particles–fed continuously into the FBR chamber– to deposit more polysilicon onto its surfaces, causing the particles to grow. The resulting product is large granules of polysilicon ready for use in producing the mono- and multi-crystalline silicon wafers we are more accustomed to seeing.

In comparison, the Siemens process works by placing large pre-fabricated rods of silicon in a chamber with superheated silicon-rich gas. At high temperature, solid silicon deposits onto the polysilicon rods, causing them to expand. As part of the process, the chamber walls must be cooled to prevent silicon deposition onto that surface. This essentially creates a situation whereby a furnace is placed within a refrigerator, leading to significant inefficiencies and high energy use.

The average PV consumer will not visually see a change in modules produced with FBR technology but they will see the drop in prices. The 2014 International Technology Roadmap for Photovoltaics estimates FBR technology will account for approximately 45% of polysilicon market share by 2024 so there is every reason to expect the cost of modules to continue dropping.

Top Image Credit: REC

© 2014 Solar Choice Pty Ltd

Dear John congratulations on both your achievements and your enthusiasm. I am at the solar to storage design interface and anything you could now go on to encourage in this solar to economic off grid storage fo

homes upwards to remote and third world communities would be very well received. Good luck with your chosen missions.