A new European Commission-funded research project may bring organic solar cells closer to commercialisation.

Germany’s Karlsruhe Institute of Technology (KIT) recently announced the creation of the “MatHero” project supported by the European Commission to the tune of EUR 3.5 million. The project, coordinated by KIT, is aimed at bringing organic photovoltaics on par with silicon, thin-film and other inorganic PV technologies, with the end goal of developing an environmentally friendly printed organic solar module for off-grid applications.

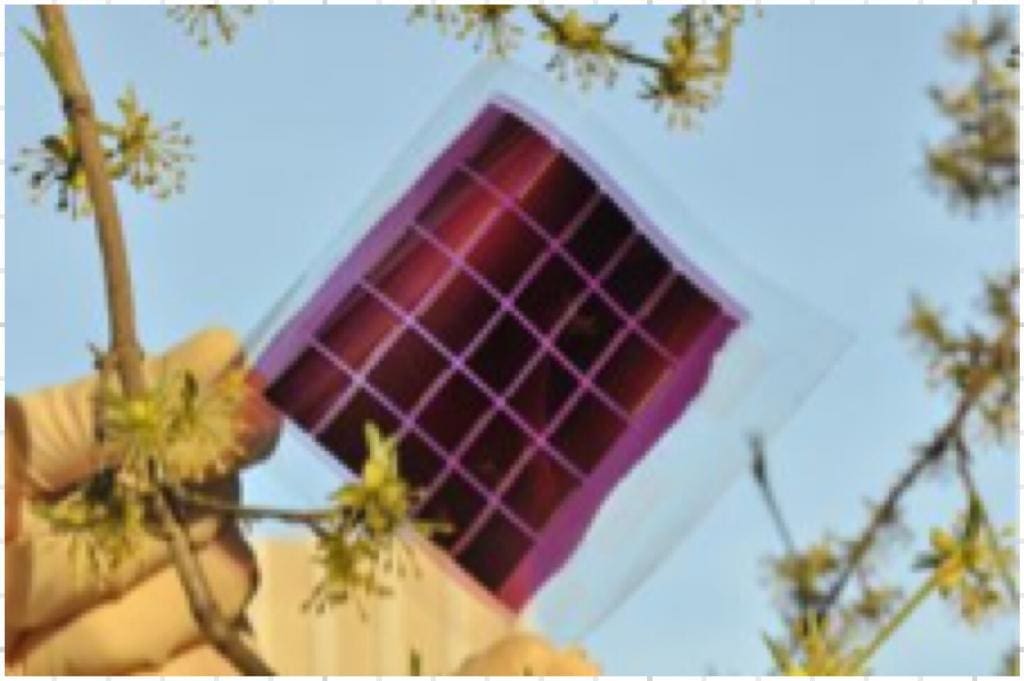

Organic solar cells are light-weight, flexible and can be made in various colours, allowing them to be custom designed in ways standard photovoltaic technologies simply cannot be. Due to these advantages, organic solar cell technologies may unlock new markets for photovoltaics if they can be successfully commercialised.

Some aspects of organic solar cell do, in fact, make them suitable for large-scale production. For example, organic PV cells can be produced using energy and resource-efficient printing processes, promising lower costs and higher production volumes. However, in order for organic solar cells to compete with incumbent PV technologies, scientists will need to demonstrate higher efficiencies, lower cost production methods and most importantly – improve the reliability of the cells to make them longer lasting.

Image Credit: Andreas Pütz / Karlsruhe Institute of Technology

Although recent advances in technology have pushed energy conversion efficiencies of lab-scale organic PV devices past the 10% mark, it is still much lower than efficiencies routinely offered by incumbent technologies in commercial production (14-20%). Also, since organic cells are made mostly from chemicals, reducing the costs and the environmental impacts associated with synthesizing of the materials is important to ensuring the technology reaches the market place.

Further, the nature of the chemistry used to create most organic PV cells makes it difficult to create long-lasting devices. For example, typical lab-scale organic PV cells degrade within a few hundred hours, although lifetimes of a few thousand hours (less than a year) have been achieved and researchers believe that future advances in packaging could result in 3-20 year lifetimes in the future. In contrast, commercial solar panels are typically guaranteed for 25 years and have extensive field-test data to support claims for reliability.

The “MatHero” project aims to address these problems by creating a multi-disciplinary consortium of physicists, chemists, materials scientists, and engineers who will research on various technological and product development aspects. This includes all aspects of organic solar cell fabrication from the design and production of the polymer precursors used for cell fabrication to packaging and characterization of the modules and the assessment of device stability.

The project will also focus on developing environmentally friendly chemical processes for materials synthesis, coating and printing technologies. As KIT’s Dr. Alexander Colsmann explains, “The use of environmentally compatible solvents is a major prerequisite for cost reduction, as complex safety measures on the industrial scale will no longer be required.”

If the project manages to achieve its goals of enhanced efficiency, reduced production costs, and increased life-times, organic PV technology could come to the market sooner than expected.

Top Image Credit: Alexander Colsmann / Karlsruhe Institute of Technology

© 2014 Solar Choice Pty Ltd

- Future of Utilities – Part 1: The death of base-load generators - 11 September, 2014

- Sharp enters energy storage market with SmartStorage - 18 August, 2014

- Phinergy extends electric car range with metal-air battery technology - 13 August, 2014